Guinea Local Manufacturer of China Sinotruk

Guinea Local Manufacturer of China Sinotruk

Guinea Local Manufacturer of China Sinotruk

Guinea Local Manufacturer of China Sinotruk

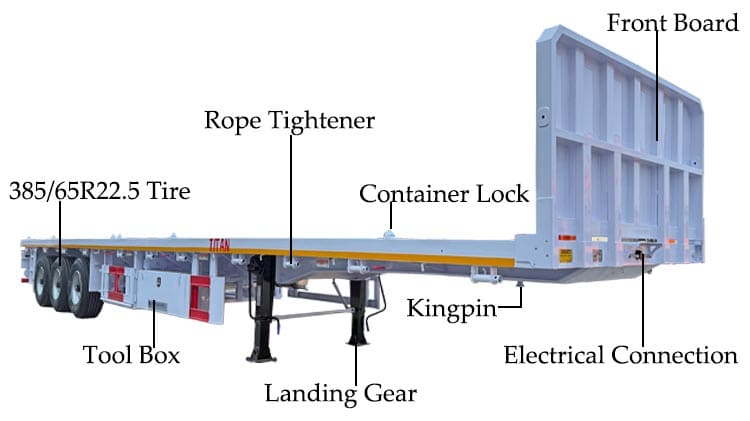

The tri axle 40 ft flatbed semi trailer is engineered to perform reliably across diverse terrain conditions, whether on inland gravel roads or in humid coastal zones. Designed for both containerized cargo and bulk transport, offers flexible logistics options, making a preferred solution for various operational needs.

Capable of accommodating both 20-foot and 40-foot standard containers, the flatbed semi trailer price serves as a vital link between port operations and inland distribution networks. The structure effectively disperses cargo weight across the frame, minimizing stress concentration on any single point. The approach reduces the likelihood of frame deformation or fatigue, thereby extending the flatbed semi trailer service life and maintaining structural integrity during transportation.

Dimension: 12500mm*2500mm*1550mm

Trailer Future: with front board

Loading capacity: 60 ton

Side Beam: 160mm high

Axles: 3 axles, TITAN brand, 13 ton

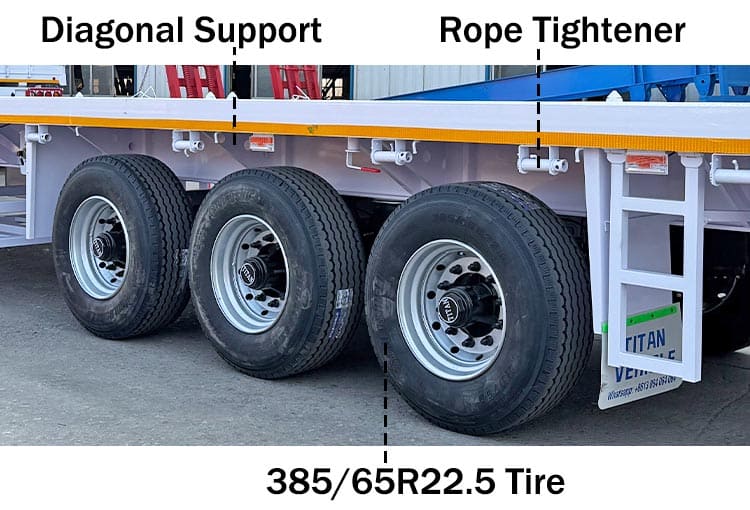

Tire: 385/65R22.5, 12 units

Suspension: mechanical suspension

Leaf Spring: 10 layers

Bumper: 4mm thickened bumper

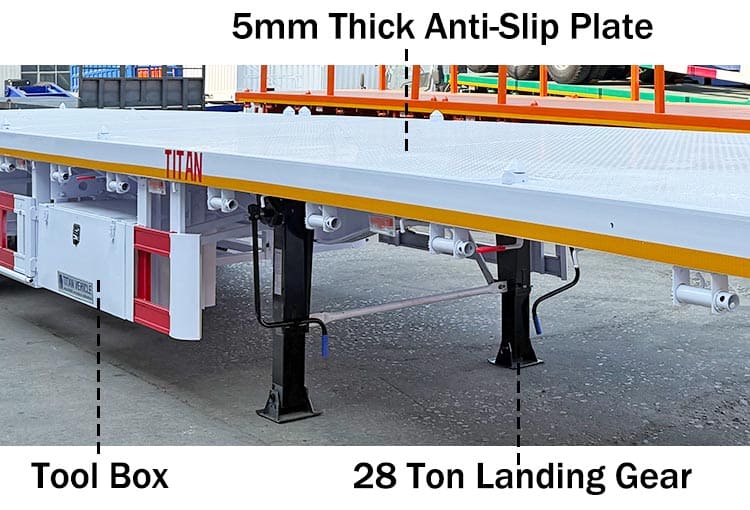

Landing Gear: 28 ton

Lamp: LED lamp with anti-theft net

For rust prevention during long-distance maritime transport, TITAN applies a comprehensive protection method before delivery. Each 40 ft flatbed semi trailer is coated with a layer of protective wax and wrapped in waterproof covering, providing strong resistance against moisture, sea spray, and corrosive salt air. The packaging approach ensures that the flatbed semi trailer price arrives in excellent condition, ready for immediate deployment.

Customers can choose between two main shipping options, containerized delivery or roll-on/roll-off (RORO) shipping, depending on the logistical requirements and destination conditions. The flexible delivery method helps meet varied operational schedules and reduces turnaround time.

Constructed with a focus on strength and durability, the TITAN flatbed semi trailer price uses Q355 low carbon high strength alloy steel for its main beam. The material choice ensures enhanced rigidity and load-bearing capacity. The frame components are assembled using submerged arc welding technology, which helps form strong, seamless joints. The process not only strengthens the 40 ft flatbed semi trailer core but also improves its ability to withstand long-term wear and mechanical stress.

Additional reinforcements of the flatbed semi trailer price are incorporated into high stress areas, particularly around the gooseneck where load-bearing pressure is more intense. Double-layered reinforcement in the section ensures better pressure resistance and helps maintain stability under heavy loads. The combination of material quality and structural reinforcement boosts overall performance, making the flatbed semi trailer more resilient in demanding transport scenarios in Guinea.

To further strengthen the 40 ft flatbed semi trailer chassis, the cross members are securely fixed to the main beam using diagonal bracing. The distance between braces is kept within 500mm to ensure balanced force distribution and prevent frame distortion. Moreover, each cross member is made of 100mm thick channel steel, which supports optimal performance even under heavy load conditions.

The surface finishing process plays an important role in extending the 40 ft flatbed semi trailer service life. A powder coating combined with baking paint technology is applied, which enhances surface resilience and provides a clean, glossy appearance. Although the application process is costlier than traditional paint, the long term benefits are significant. The coating resists peeling and fading caused by exposure to intense sunlight, which is particularly advantageous for regions like Guinea. As a result, reduces the need for frequent repainting and minimizes maintenance efforts.

In terms of components, the flatbed semi trailer price is equipped with 13-ton axles, known for the robust performance and reliability. These axles are better suited for Guinea rough road conditions, capable of absorbing the impact of continuous vibration, gravel, and uneven surfaces. The improved axle strength not only increases the load capacity—up to 60 tons—but also lowers the chances of structural damage due to overloading, ensuring safer and more stable transport.

One of the flatbed semi trailer most functional features is its open deck design. It supports both bulk cargo and containerized transport with equal ease. The 40 ft flatbed semi trailer platform comes with 12 container locks pre-installed, allowing operators to quickly and securely fasten containers. The setup reduces operational time and simplifies the loading process, while ensuring that the container remains firmly in place throughout the journey.