Guinea Local Manufacturer of China Sinotruk

Guinea Local Manufacturer of China Sinotruk

Guinea Local Manufacturer of China Sinotruk

Guinea Local Manufacturer of China Sinotruk

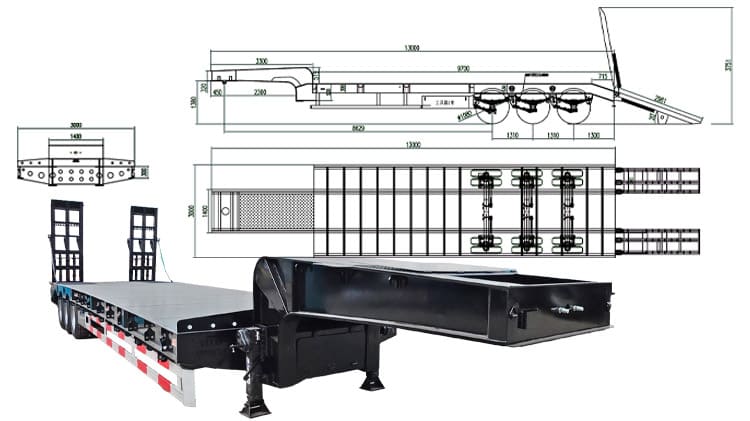

With its low center of gravity and wide platform, the low bed trailer is capable of transporting large, irregularly shaped equipment. The design makes well-suited for use across multiple industries, including agriculture, construction, and other heavy-duty applications.

The 40 feet low bed trailer is specifically designed for heavy-load transport by optimizing its overall structure and reinforcing key components. Its floor is built to resist deformation, offering stable and secure support for operations involving large equipment, such as construction machinery or agricultural vehicles. The reinforced parts of the low bed trailer enhance load stability and ensure better compatibility with both loading and unloading conditions.

Floor Plate: 5mm thickened pattern plate

Side Beam: 300mm high, 8mm thick

Tire: 12 units, 12R22.5

Axles: 3 axles, 13ton, TITAN brand

Ramp: 16mm thick spring ramp

Suspension: mechanical suspension

Leaf Spring: 10 layers

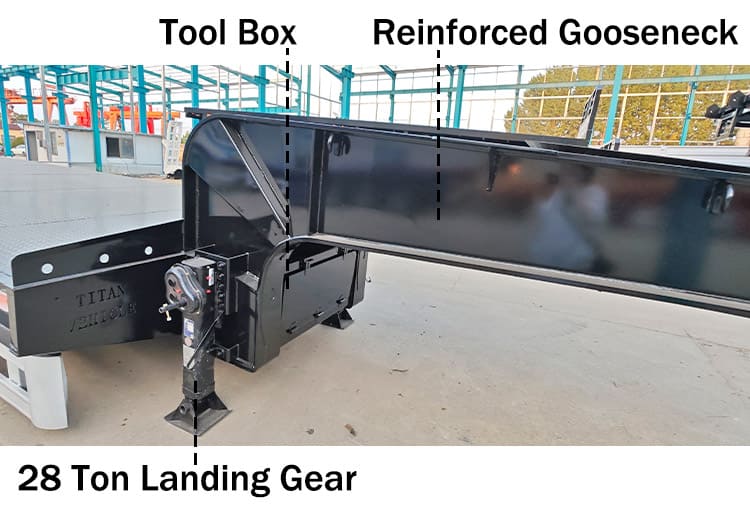

Landing Gear: 28 ton

Lamp: LED Lamp

To improve safety during transport and minimize the risk of cargo slippage, the low bed trailer price floor is made from a 5mm thick patterned steel plate. The material not only increases the overall load-bearing strength of the platform but also boosts surface friction. The added grip helps to prevent equipment from shifting on Guinea uneven or bumpy roads.

The thicker floor plate not only improves compression resistance but also allows the low bed trailer to better handle the complex road conditions commonly found in Guinea, further enhancing the safety and reliability of heavy-duty transport.

Loading heavy machinery requires driving onto the 3 axle 40 feet low bed trailer using the rear ramp. For customers in Guinea, a major concern is whether the ramp can handle the stress of repeated use. To address, the 60 tons low bed trailer price features a spring-assisted ramp constructed with a strengthened frame and a 16mm thick spring.

The design offers solid support and ensures the ramp remains durable during frequent loading. The ramp mechanism is simple, allowing to be raised and lowered easily, even by a single operator, making suitable for a variety of operational needs.

To further secure equipment during transit, rope tensioners are mounted on both sides of the low bed trailer. These devices help prevent cargo from shifting or falling off during sharp turns or sudden braking. The tensioners are easy to operate, improving the efficiency of securing the load and serving as essential accessories for maintaining safety during transport.

The main beam of the 40 feet low bed trailer is made from Q460 high-strength steel, which offers excellent resistance to deformation and is well-suited for carrying heavy loads. At the same time, the gooseneck section features a double-layer reinforcement design. The enhancement strengthens the low bed trailer price structural resistance to stress and helps reduce the risk of deformation when under extreme pressure, thereby increasing the low bed trailer durability and load handling capacity.

Before the low bed trailer price hits the road, low bed trailer must be connected to a tractor unit, making the durability of the traction plate an important safety consideration.

The 40 feet low bed trailer uses a traction plate made from a single piece of steel, maintaining the structural integrity of the connection. With a thickness of 12mm, the traction plate not only transfers pulling force evenly but also provides buffering against sudden impacts, adding an extra layer of protection during transport.

The axle of the 40 feet low bed trailer plays a vital role in bearing and distributing load pressure. Compared to standard axles, TITAN 13 ton axles are designed to more effectively spread the weight across the frame and tires, reducing the risk of tire blowouts or frame damage caused by excessive pressure in a single area. The design enhances overall transportation safety and stability.

To prevent rust during sea transport and exposure to variable weather conditions, each 40 feet low bed trailer for sale goes through a multi-step protection process before delivery. First, a layer of protective wax is applied to create a shield against moisture. Then, the entire low bed trailer is wrapped in a waterproof covering. These protective measures are effective against temperature changes and humidity, helping to keep the low bed trailer in excellent condition throughout transoceanic shipping.