Guinea Local Manufacturer of China Sinotruk

Guinea Local Manufacturer of China Sinotruk

Guinea Local Manufacturer of China Sinotruk

Guinea Local Manufacturer of China Sinotruk

One of the 100 ton low bed trailer price standout features is its enhanced loading and unloading efficiency. The low deck design, combined with a reinforced spring-assisted rear ramp, simplifies the movement of heavy machinery. The setup minimizes the need for external lifting equipment, saving significant time and reducing labor costs—an especially valuable advantage for customers in Guinea managing heavy transport projects.

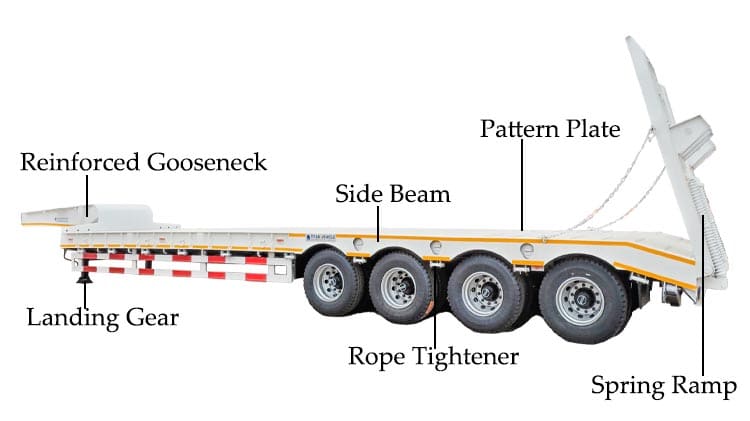

Overall Dimension: 13000mm*3000mm*1710mm

Side Beam: 300mm high, 8mm thick

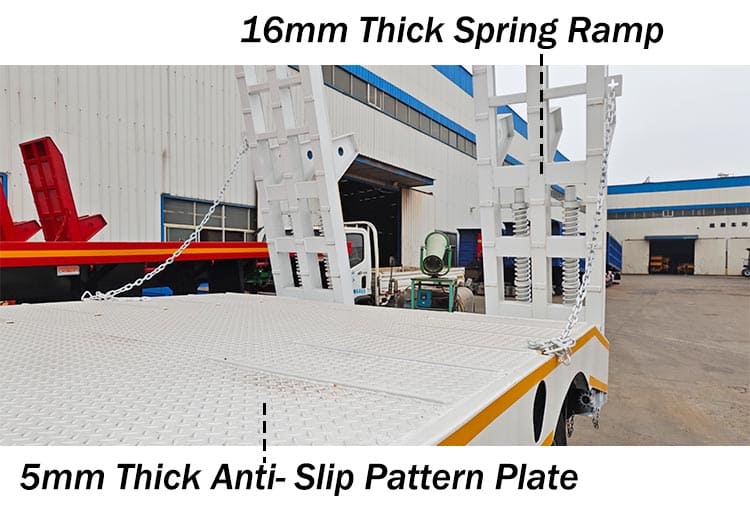

Floor Plate: 5mm thickened pattern plate

Axles: 3 axles, 13ton, TITAN brand

Tire: 12 units, 12R22.5

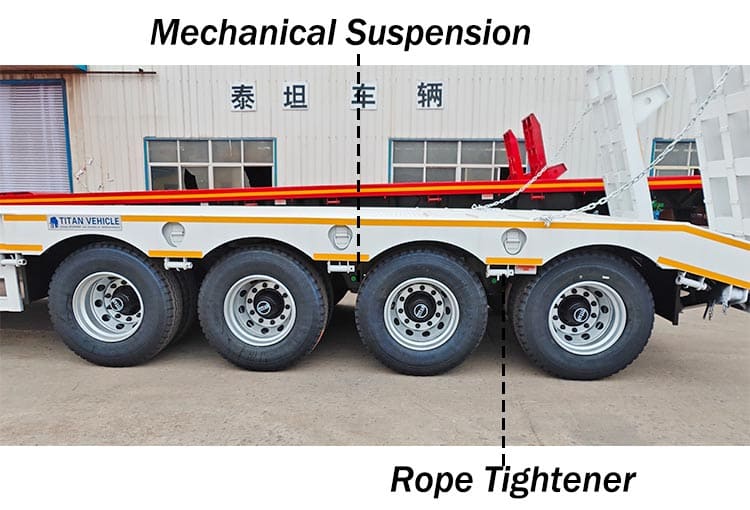

Suspension: mechanical suspension

Leaf Spring: 10 layers

Ramp: 16mm thick spring ramp

Landing Gear: 28 ton

Lamp: LED lamp

The primary load-bearing structure of the low bed trailer price centers on a main beam made from Q460 high strength steel. This material offers superior tensile performance and greater load capacity compared to standard steel. To further strengthen the structural core, the gooseneck section is reinforced with a double-layer vertical plate system. The composite structure effectively limits deformation, even when the 100 ton low bed trailer is under extreme loads, ensuring safe and stable transport operations throughout the journey.

Unlike traditional low bed trailers that use smooth steel decks, the TITAN 4 axle low bed trailer features patterned steel plates on its cargo platform. These 5mm thick high strength plates include a raised, textured surface that increases grip and traction, improving resistance against equipment shifting during transit. The pattern design balances frictional resistance with structural reliability, helping keep cargo stable even on long or difficult routes.

For added durability, the surface of the 4 axle low bed trailer undergoes a two-step coating process. First, a powder coating is applied, followed by a baking paint treatment. The protective finish improves resistance to corrosion and fading, making especially effective in harsh environments like those commonly found in Guinea. The surface maintains its appearance and integrity longer, reducing the frequency of repainting and touch-up work.

Supporting heavy duty operations, the rear ramp has been specifically designed for strength and ease of use. A 16mm thick ramp panel is supported by strong springs that absorb impact as equipment is loaded onto the low bed trailer price. The spring-assisted function not only ensures a smooth transition between the ground and the low bed trailer deck but also allows a single operator to raise or lower the ramp efficiently. This design enhances convenience on job sites where equipment loading time is critical.

To secure machinery during transportation, the 100 ton low bed trailer is equipped with multiple rope tightener distributed along both sides of the frame. The fasteners, integrated into a coordinated layout, work together with the reinforced deck to form a robust three-dimensional securing mechanism.

The rope tighteners feature a quick-lock structure and allow precise tension adjustment with minimal effort. The system helps ensure that equipment remains firmly in place, even during sudden braking or sharp turns.

Lighting and visibility are also prioritized in the 100 ton low bed trailer design. Upgraded high-brightness LED lamps provide clear illumination and vehicle outlining in dim or foggy conditions. Each lamp is housed in a durable, impact-resistant casing that offers reliable protection against gravel and debris.

For braking performance, the low bed trailer price comes equipped with 16-ton brake pads, which deliver fast and effective response in emergency scenarios. The setup reduces stopping distance and enhances road safety during transport. The 4 axle low bed trailer piping system is made from pressure-resistant rubber, which extends the service life of key components. Meanwhile, the electrical wiring utilizes heavy-duty cables to ensure stable signal transmission and consistent functionality even in Guinea rugged conditions.

To ensure product quality during international delivery, TITAN employs a two-layer protection approach for packaging. Before shipment, each 100 ton low bed trailer is sprayed with a moisture-resistant wax coating and then wrapped in a waterproof fabric. The combined protection acts as a barrier against high humidity and sea salt corrosion during marine transport. As a result, the low bed trailer price maintain optimal condition upon arrival, ensuring reliable performance from the outset.